info@bwtec.com +41 44 863 70 70

2774 Auto Balloon Forming Machine

2774 Auto Balloon Forming MachineDownload .pdf

Fully Automated Balloon Production for high-demand medical manufacturing

The 2774 Auto Balloon Forming Machine is designed for fully automated production of plastic balloons. The electrically heated stretch blow molding process enables the production of a variety of high-quality balloons for angioplasty and other medical applications.

The high-capacity tube magazine can hold up to 200 plus necked tubes (Tube dependent). These are automatically loaded into the mold. After the rapid forming process, the balloons are issued into the storage tray. The balloons can be retrieved from the balloon storage container during the process.

Enhanced Efficiency with Reliable Quality

Designed to support scalable, efficient, and high-quality balloon production, the 2774 Auto Balloon Forming Machine is the ideal solution for high-demand medical manufacturing environments.

User-Friendly Controls and Connectivity The machine is equipped with a PLC, touch-screen PC, and the intuitive BW-TEC HMI, ensuring easy operation and recipe management. With network compatibility, the 2774 Auto Balloon Forming Machine integrates easily with production databases, storing product-specific process parameters in dedicated recipes for streamlined operations.

Key Features

- High-Capacity Tube Magazine: Holds up to 200 plus necked tubes (depending on tube size) for extended, continuous production, with automatic loading into the mold.

- Efficient Collection System: Finished balloons are issued directly to a storage tray for easy, uninterrupted access and retrieval during production.

- Fully Automated Workflow: The seamless, fully automatic process enhances productivity and quality, allowing operators to allocate resources more effectively.

- Compatible with BW-TEC heating blocks and balloon molds, offering seamless integration into your existing setup.

| Technical Specifications: | |

|---|---|

| balloon diameter: Ø 4–34 mm | |

| balloon length: 2–110 mm | |

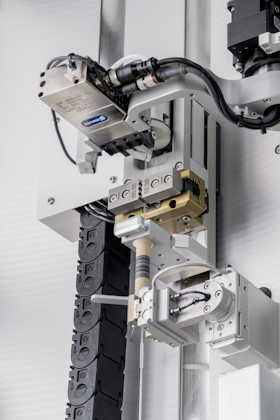

| Vertical Rapid Heating Block | |

| up to 200 balloons per magazine (tube size dependent) | |

| process temperatures: 20–250 °C (68–482 °F) | |

| cooling with chiller (included) | |

| process time: 1–3 min (for a typical PTCA Balloon) | |

| process pressure: 0–50 bar (0–725 psi) | |

| low pressure system: 6-8 bar (87–116 psi) | |

| linear stretching way: up 750 mm, down 400 mm | |

| servo motors | |

| user interface with BW-TEC HMI | |

| PLC Controller and PC for HMI and data management, network compatible | |

| dimensions (L x W x H): 1050 x 720* x 2240* mm *incl. screen ~1050 x 1150 x 2240 mm | |

| weight without chiller: 315* kg *incl. chiller 355 kg | |

| power: 3 x 230 VAC, 16 A, 2000 W |