info@bwtec.com +41 44 863 70 70

2430 Balloon Forming Machine

2430 Balloon Forming MachineDownload .pdf

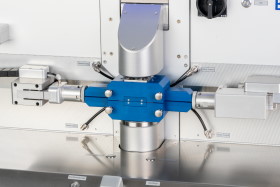

The 2430 Balloon Forming Machine is designed to produce a variety of soft balloons. The electrical heated stretch, pump-blow molding process allows the production of different high-quality balloons for medical applications. The split mold allows the production of different balloons with complicated shapes. The standard mold is particularly suitable for OEM applications and features a fast balloon mold change.

The machine is equipped with a user-friendly HMI, which completes the operation of the system via the touch screen. Due to the network compatibility the machine can be integrated in the company network. The process parameters for the different products can be stored in separate recipes.

| Technical Specifications: | |

|---|---|

| up to 150 balloons per shift | |

| process time: 2–6 min | |

| process pressure: 0–10 bar (0–145 psi) | |

| max. tool size: 50 mm x 50 mm | |

| process temperatures: 20–200 °C (68–392 °F) | |

| cooling with integrated system | |

| low pressure system 6–8 bar (87–116 psi) for product fixation | |

| linear stretching distance: left/right 450 mm | |

| integrated flow and force measurement | |

| minimal tube length before stretching: 25mm | |

| servo drives | |

| barcode scanner for balloon form detection | |

| quick exchange system for the fast change of the molds | |

| simple user interface with BW-TEC HMI on touchscreen | |

| PLC controller and PC for HMI and data management, network compatible | |

| dimensions (L x W x H): 1500 x 750 x 1350 mm | |

| weight: 120 kg | |

| power: 110 or 230 VAC / 2000 W others upon request |